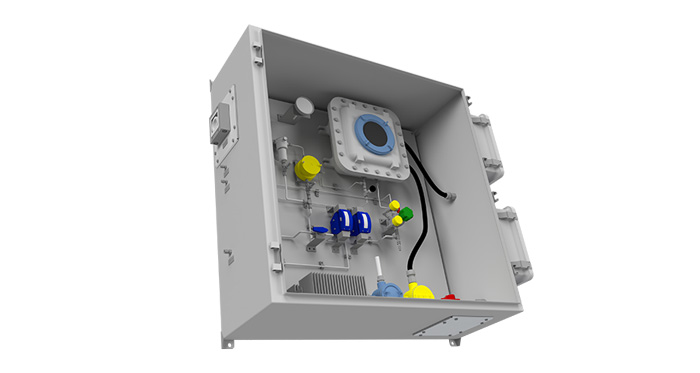

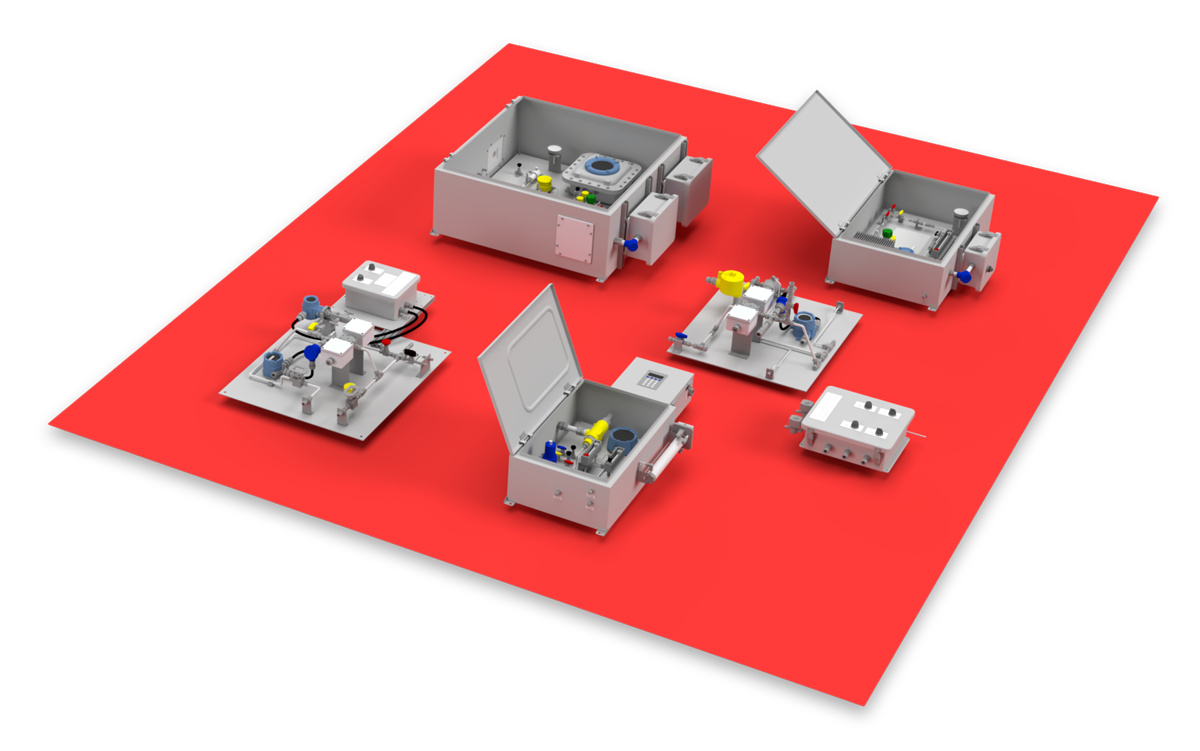

Welcome to Insight Analytical Solutions, where we specialize in seamless system integration. With our innovative solutions and cutting-edge technology, we can help you achieve your goals and take your business to the next level. Let us help you unlock the full potential of your systems and revolutionize the way you work.

Learn More

We treat our customers as partners, striving to inform, educate, and mentor them. We use strategic techniques and technology to improve their operations.

Hard work and dedication are at the heart of our success. Our team works tirelessly to deliver quality projects and exceptional service to our customers.

We value open-mindedness, improvement, and a willingness to learn from mistakes. Our commitment to growth sets us apart as individuals and as a company.

Unity and cohesion are essential to success in our ecosystem. We prioritize doing the right thing, choosing courage over comfort, and living with honesty and respect.