Description

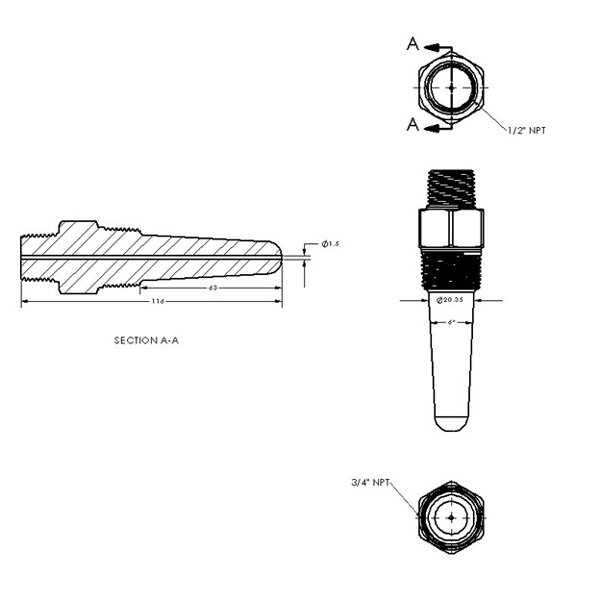

This probe is the product of an effort to design a standard sample probe that will work in most gas phase analytical applications with a 3/4” NPT threadolet process connection. In addition to the 3/4” male NPT thread for the process connection, another male ½” NPT connection is included for an isolation valve. It has an insertion length of 63 mm from the base of the NPT thread, or about 50 mm (2 inches) as measured from the inside wall of typical process pipes. This length is sufficient to obtain a representative sample in most applications.

The quill section of the probe has a 1.5 mm bore for fast response time, a hemispherical tip to reject particulates and liquid aerosols, and follows the Insight Analytical philosophy of eliminating excessive probe insertion length. Electropolishing the 316L stainless steel smooths and passivates the surface, which results in improved corrosion resistance, higher fatigue strength, and reduces the tendency for thread galling.

For most gas phase applications, the common practice of specifying probe length to locate the tip in the center third of the pipe typically results in a probe that is much longer than required to obtain a representative sample. The elimination of excess sample probe length lowers cost, improves response time, makes plugging less likely, reduces pressure drop and flow disturbances in the process pipe, and makes it possible to design the probe to withstand high process gas velocity without failure caused by vortex shedding induced vibration. This probe has been designed to meet the vortex shedding safety calculations in the ASME PTC 19.3 TW-2010 thermowell design standard for fluid velocities up to 100 m/s and fluid density up 0.4 kg/m3.