Quality Control: Blending allows producers to meet specific product quality standards and regulations, such as reducing sulfur content to comply with environmental requirements.

Economic Optimization: It can improve the economic viability of refining by maximizing the yield of high-value products like gasoline, diesel, or jet fuel.

Market Demand: Adjusting the blend can help match the product portfolio with market demand, ensuring a competitive edge.

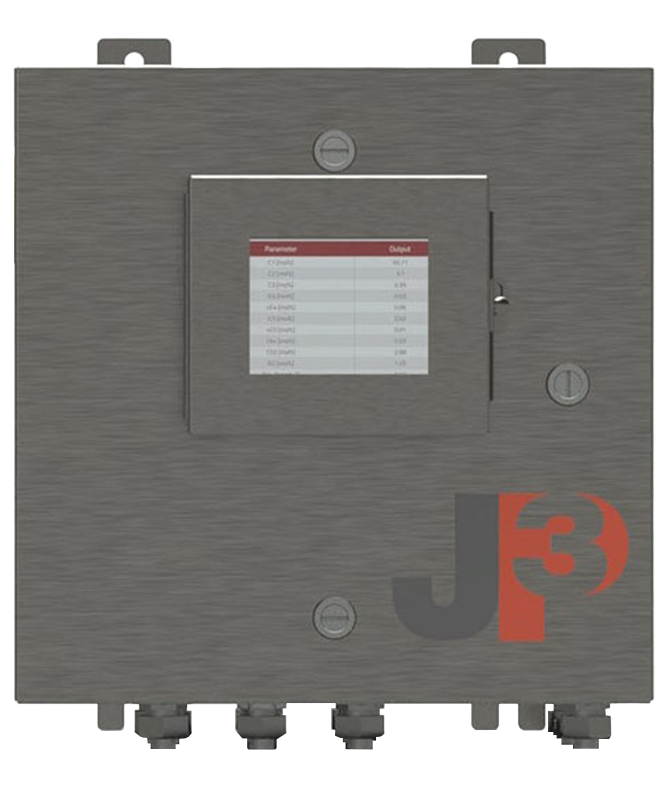

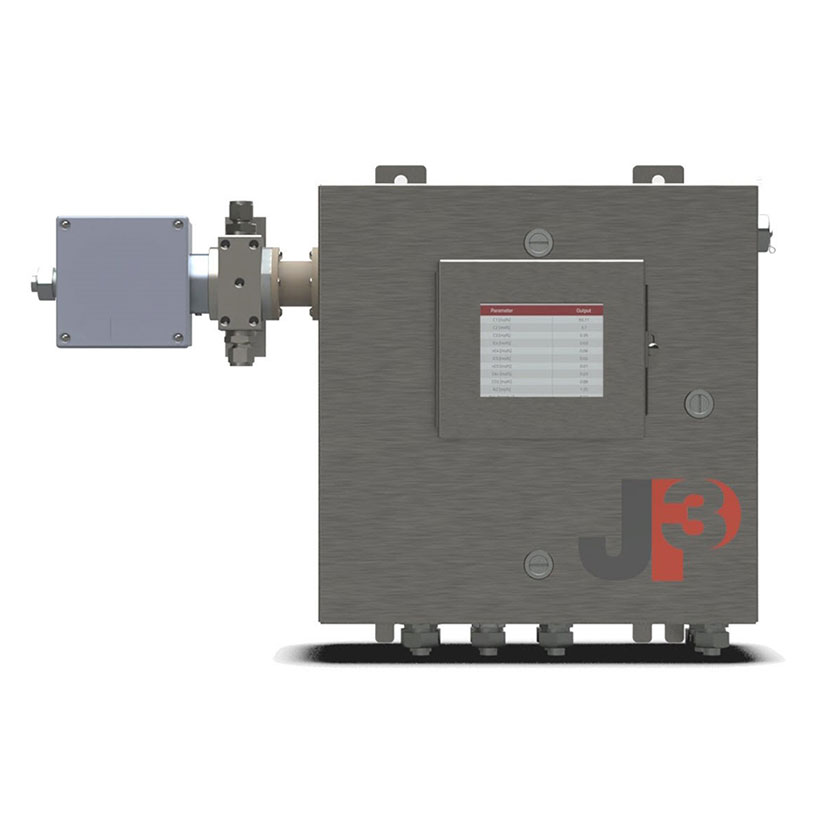

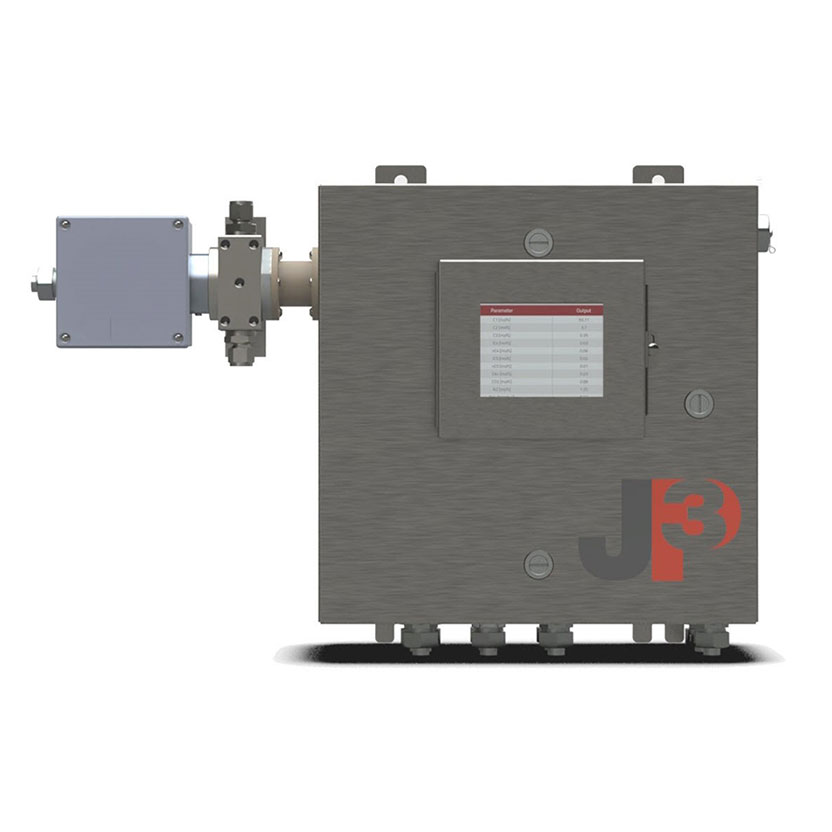

Enhanced Performance: The Verax CTX is equipped with four independent spectrometer detectors, enhanced optical components, and a new flow cell. These enhancements translate to faster measurement times, improved measurement quality, exceptional repeatability, stability, and reliability, even in the harshest environments.

Comprehensive Analysis: The Verax CTX can accurately analyze natural gas or liquids to obtain vital information such as hydrocarbon composition, Vapor Pressure, BTU (British Thermal Unit), API gravity, and other critical physical properties. It is also certified for Natural Gas Custody Transfer applications, ensuring compliance with industry standards.

Eco-Friendly: JP3's advanced technology ensures that Verax analyzers produce zero emissions and require no carrier/calibration gases, contributing to a sustainable and environmentally responsible approach to analysis.

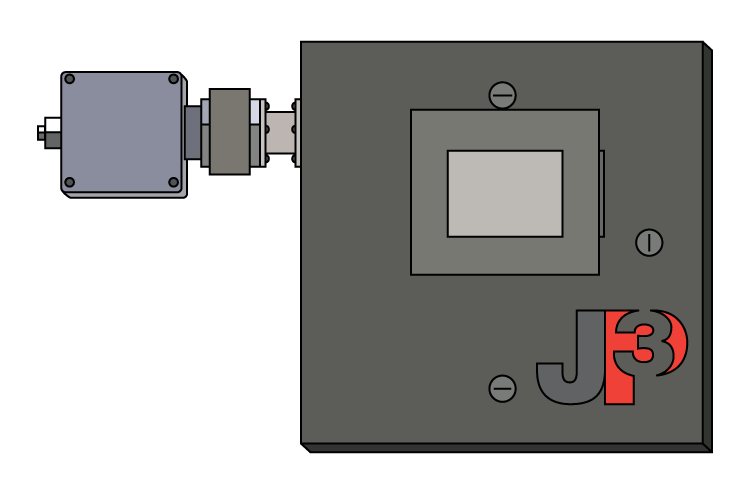

Fast Stream Composition: The SSL provides quick stream composition analysis of C1-C9+, BTU, API gravity, Vapor Pressure, and more with excellent repeatability and reproducibility, making it a valuable tool in the blending process.

Environmentally Friendly: Just like the Verax CTX, the SSL produces zero emissions and doesn't require carrier/calibration gases, aligning with environmentally conscious practices.

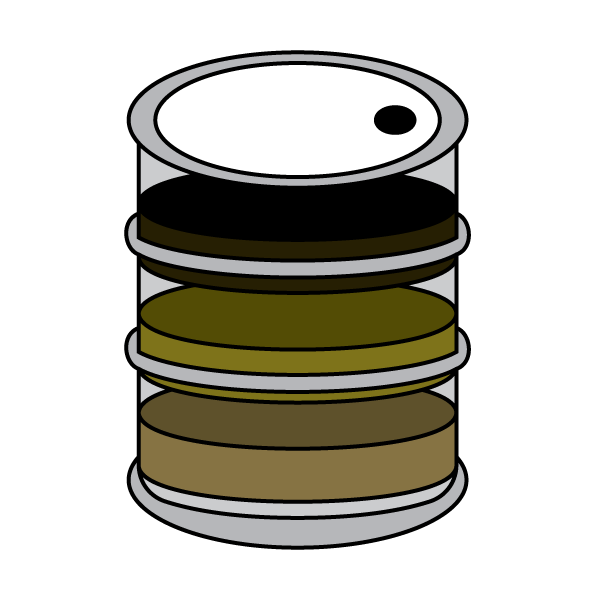

Versatile Performance: This compact and robust X-ray Transmission / Absorption (XRT / XRA) process gauge is specifically optimized for total sulfur analysis in refineries, pipelines, blending operations, bunkering terminals, and storage facilities.

Wide Range of Applications: The NEX XT is well-suited for various applications, including bunker fuel blending to meet MARPOL Annex VI sulfur restrictions, interface detection of different grade fuels delivered via pipelines, refinery feedstock blending and monitoring, and quality monitoring of crude at remote collection and storage facilities.